Research Projects

"Investigation of integrated effect of the riveting process and applied loading on the fatigue behaviour of riveted lap joint in aircraft fuselage". Project No. 2011/03/B/ST8/05473, founded by National Science Centre (Poland)

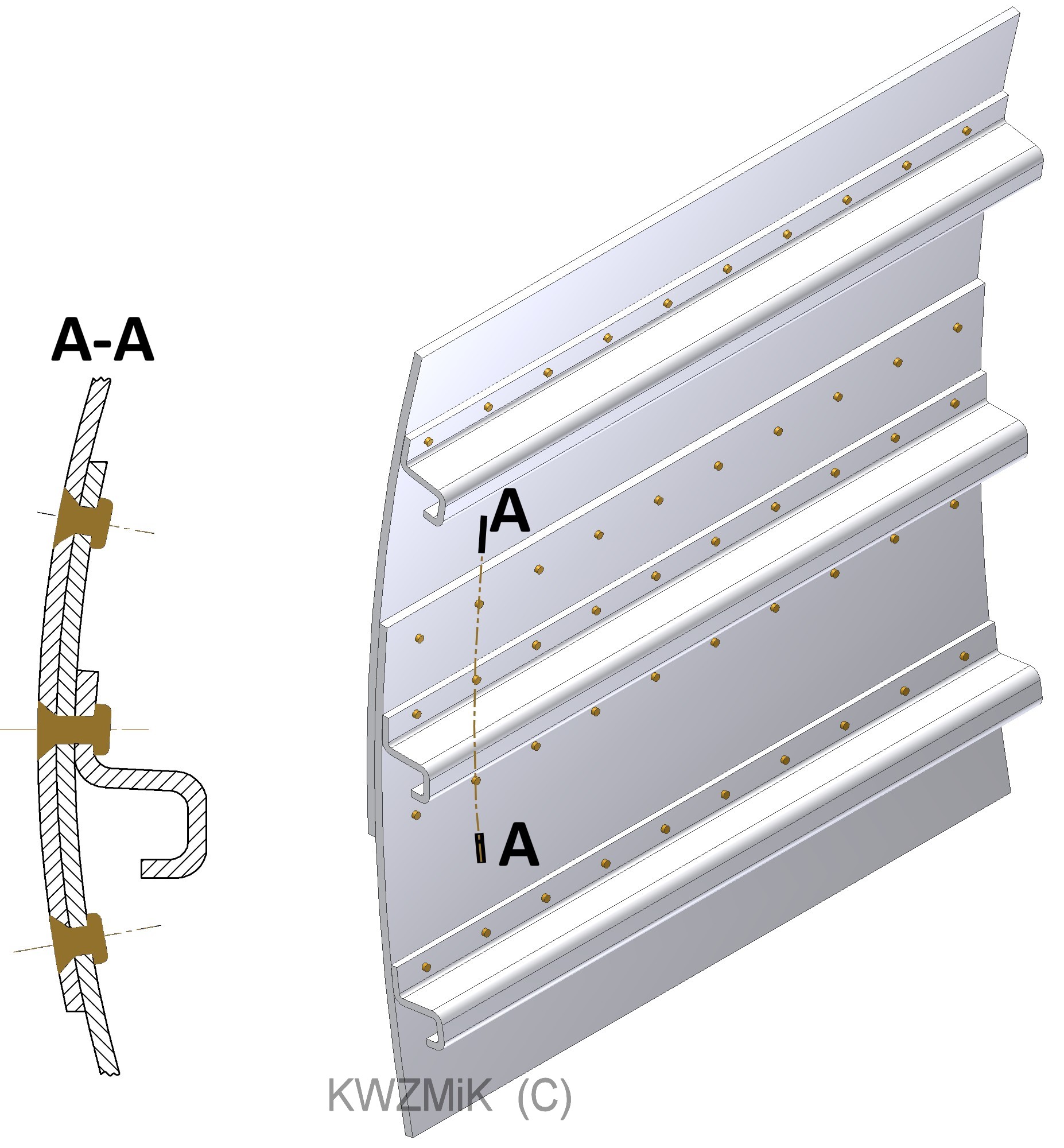

The fuselage of transport aircraft at high cruise altitude can be compared to a thin-wall pressure vessel. Because the internal pressure is higher than the atmospheric pressure outside, it can cause a tearing of the sheets along riveted lap joint connections of the skin, which are among the weakest spots of the structure (Fig. 1). Each flight implies a single loading cycle and cumulative fatigue damage generated under this type of loading can lead to a catastrophic failure. In view of that a considerable research effort is put into fatigue life predictions for riveted joints. Because fatigue properties of a riveted joint are considerably affected by the riveting process and coating of the sheets, the fatigue life prediction model developed by the present authors accounts for these factors, which is in contrast to other available prediction approaches. This increases the model transferability and allows for more reliable prediction results, thus contributing to an increase in operational reliability of aircraft.

Fig. 1

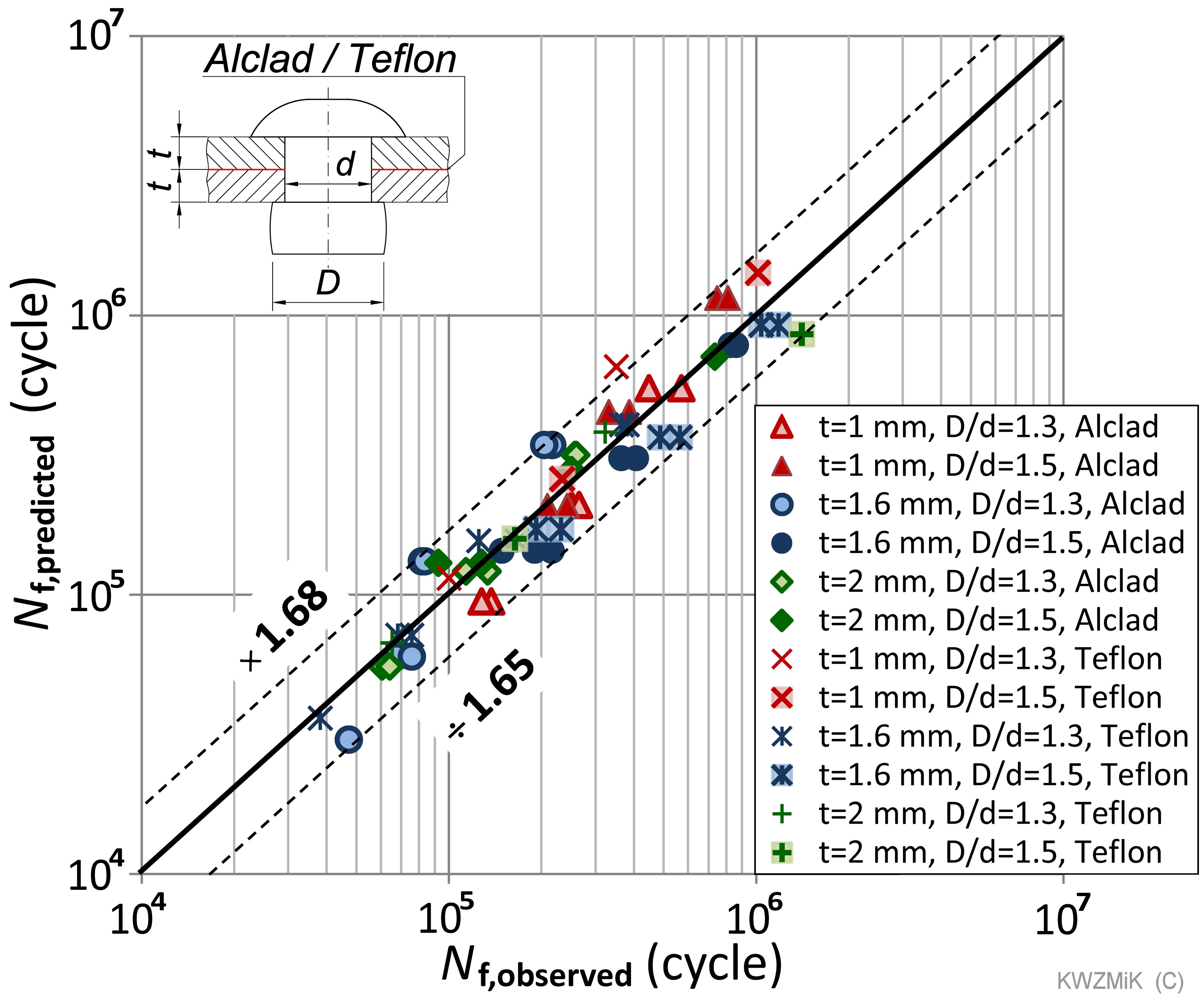

An exemplary application of the model is shown in Fig. 2, where the riveting process is represented by the D/d parameter and the effect of coating is accounted for by inserting a thin Teflon layer between the Alclad sheets in order to eliminate friction. The diagram reveals a very good agreement between the fatigue lives (Nf) of riveted lap joints experimentally observed and predicted using the model. The dashed lines indicate the scatter bounds.

Fig. 2